Download our full catalog

Products/Dredging Pumps/Dredging Pump 3"

Dredging Pump 3"

Movable Nozzles

Strength and high performance

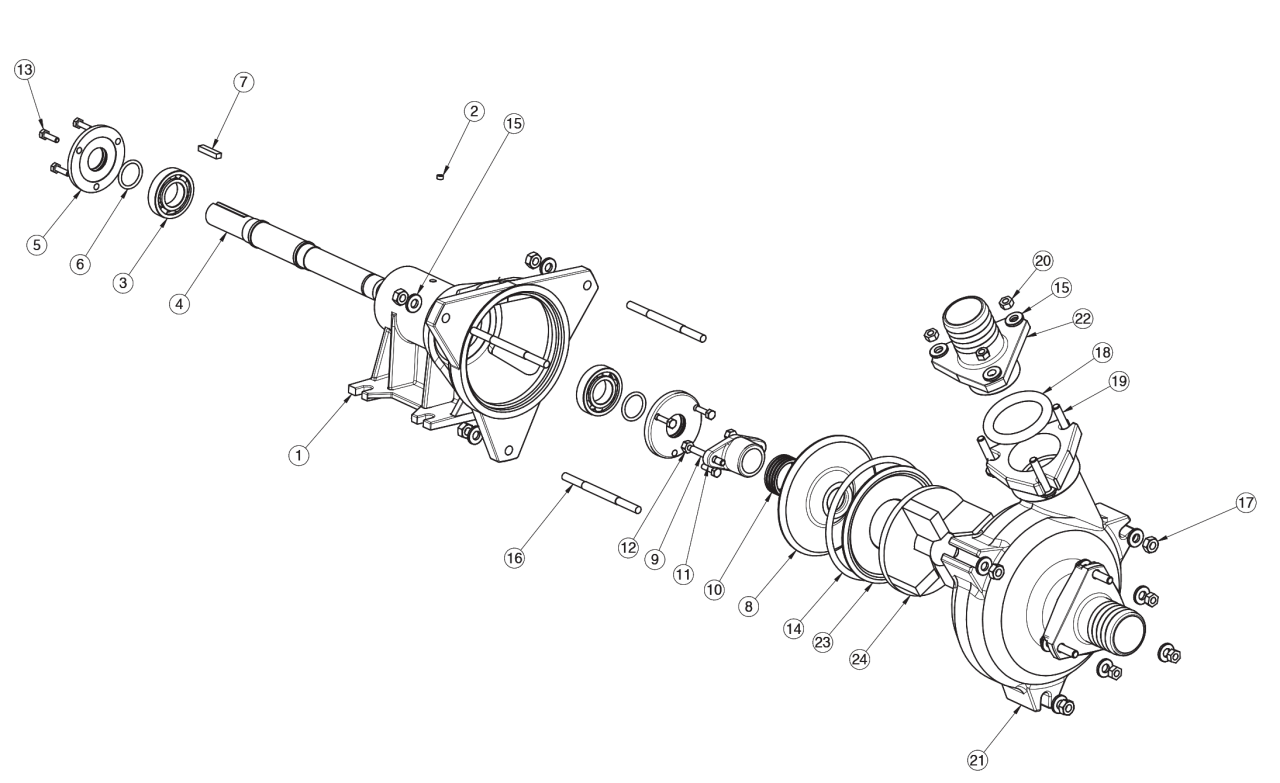

Dredge pump with movable (screwed) suction and discharge nozzles that makes and easier maintenance in case of dredging solids that may get stuck in the rotor.

BRL 2.465,00*

*The informed value is refered to the price list defined for cash for individual sales, available for pick-up at our factory (no freight included). For special deals, multiple product quotes on the same order that includes shipping, different terms for payment, or exports, you must contact the sales department to receive the supplementary information.

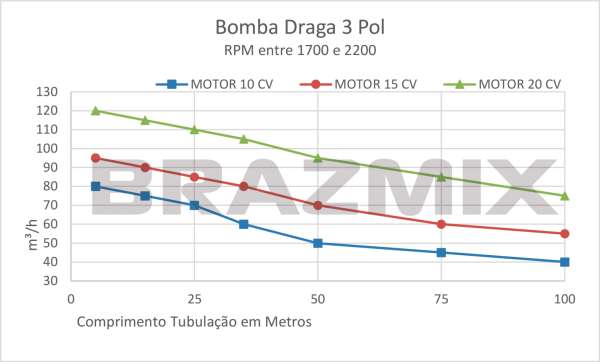

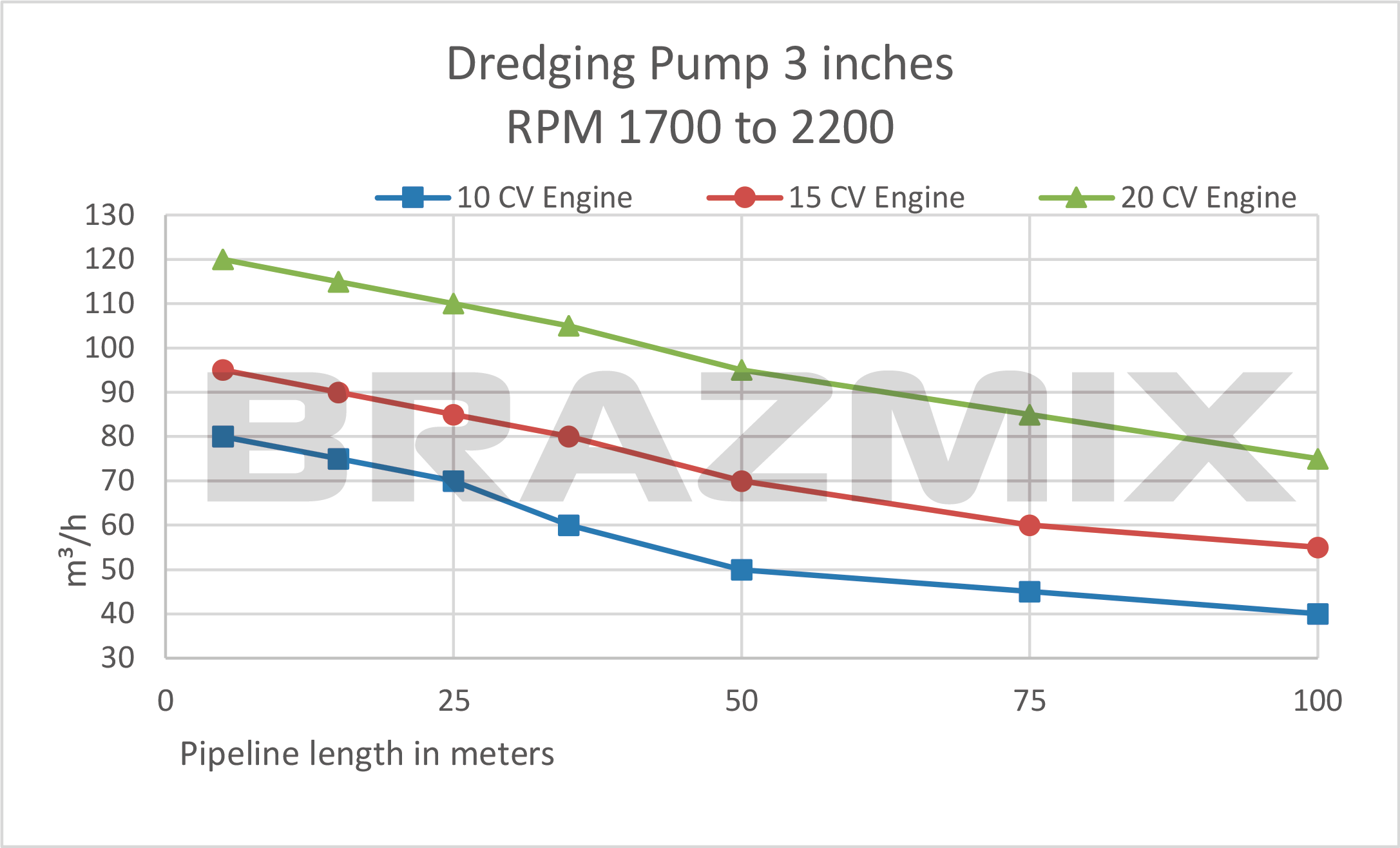

- Yields based on a reference pipeline of 100 meters in length and a 10-meter drop between intake and discharge.

- Recommended engine power (electric or combustion) is 10 hp, 15 hp, and 20 hp with continuous rotation between 1700 and 2200 RPM on the pump shaft.

- If the engine operates continuously within the RPM range accepted by the pump, direct coupling is suggested.

- If the engine operates at a different RPM range than that accepted by the pump, coupling should be done using pulleys, adjusting the engine RPM to the RPM accepted by the pump.

- Engines with lower power (hp) may work but are not recommended.

- Engines with higher power (hp) may be necessary depending on the length and drop of the pipeline in the service to be performed, but will not make the pump deliver more m³/h.

- For higher flow rate requirements, consult pump models with larger diameters.

If you have any questions about the pump's operating capabilities in your project, please contact us and speak to our technical team.

Technical description

3-inch Dredge Pump for suction of solid materials in conjunction with water (30% solids and 70% liquid).

Recommended for:

- Sand in rivers, lakes, and ponds

- Gravel and small stones in rivers, lakes, and ponds (maximum diameter of 2.5 cm)

- Mud, sludge, and well drilling residues

- Stormwater and river sewage

- Clean water (without suspended solids)

- Organic materials such as animal waste

- Flood irrigation

Not recommended for:

- Food products

- Potable water (intended for consumption)

- Organic materials with elongated fibers

- Corrosive liquids

- Concrete or similar materials

- Sprinkler irrigation or pressurized line irrigation

General Notes:

- This pump model is NOT self-priming.

- The assembly suffers abrasion wear when dredging solids, and it is impossible to say exactly how long it will last under these conditions.

- Pump manufactured from cast iron (casing, protective discs and sealing peripherals), nodular iron (bearing) and steel (rotor, shaft, bearings and screws).

- Approximate weight; 3” Pump = 75 kg

- This pump has a rotation direction that is not compatible with the rotation direction of most tractor power take-offs (PTOs), however, it is still possible to use the pump to couple to the tractor if adaptations are made during coupling. Consult additional information for this purpose.

- It is recommended to use a foot valve on the suction hose to facilitate the priming process.

The priming process is when, before starting the engine, the entire suction hose and pump housing are filled with water, ensuring that it is full before starting the engine. This process allows the pump to generate negative pressure and continue suction on its own.

- During the dredging process, the suction hose must not suck in air. This will cause it to stop operating until a new priming process is performed.

IF YOU DO NOT HAVE EXPERIENCE WITH THE ASSEMBLING AND OPERATION OF MECHANICAL EQUIPMENT, CONSIDER THE POSSIBILITY OF ASSISTANCE FROM QUALIFIED PERSONNEL.

This is a mechanical device that requires the installation of an engine and coupling. Ensure your safety when operating the assembled equipment.

This pump is manufactured from cast material that is fragile to impacts, so it is necessary to handle it carefully during installation.

If you have any questions about the operating capabilities of the pump in your project, please contact our technical team through the available means.

Related products

Easel 3 and 4 Mounted

Product made of cast nodular iron. Machined to 3 and 4 inch support dimensions with 6208 bearings (two bearings).

Equipment should primarily be assembled with the proper and original Brazmix accessories [...]

Housing 3" Brazmix

Dredge Pump Housing available in three different versions;

Iron (yellow) alloys are indicated for moving sludge, organic sediments, mud, stones and sand in low concentration. Steel (green) [...]

Impellers for Dredging Pumps

Opened 4 blades impeller made of welded steel plate, for dredge pumps from 3 til 8 inches. Good-thickness disc-reinforced weld blades to prevent warping.

Part with good support for handling [...]